Hk P30 Airsoft Spring Pistol Disassembly

Hk P30 Airsoft Spring Pistol Disassembly

Among the more than hotly predictable (or controversial, depending on who you lot talk to) Airsoft releases this past year or and then, has been the Elite Force Glock 19 manufactured past VFC. What sets this particular Glock autonomously from the many others that have stepped earlier it is that information technology is an officially licensed replica. For US based players in particular, this presents itself equally a much more accessible Glock product, as obtaining one in the by has not been without certain difficulties. Some might remember the massive blowback from Glock themselves quite a few years ago, and the myriad cease and desist messages that were sent to manufacturers, distributors and stores akin that were dealing in Glock replicas. Needless to say, if you wanted an accurately 'traded' Glock replica, you generally had to send information technology into the US in parts and pieces. The alternative was to merely accept any number of clones and copies that disused trades or fifty-fifty made meaning alternations on the physical appearance of the Glock design itself.

Among the more than hotly predictable (or controversial, depending on who you lot talk to) Airsoft releases this past year or and then, has been the Elite Force Glock 19 manufactured past VFC. What sets this particular Glock autonomously from the many others that have stepped earlier it is that information technology is an officially licensed replica. For US based players in particular, this presents itself equally a much more accessible Glock product, as obtaining one in the by has not been without certain difficulties. Some might remember the massive blowback from Glock themselves quite a few years ago, and the myriad cease and desist messages that were sent to manufacturers, distributors and stores akin that were dealing in Glock replicas. Needless to say, if you wanted an accurately 'traded' Glock replica, you generally had to send information technology into the US in parts and pieces. The alternative was to merely accept any number of clones and copies that disused trades or fifty-fifty made meaning alternations on the physical appearance of the Glock design itself.

Average retail price for the Elite Forcefulness Glock is $169 with spare mags clocking in around $44. This puts it slightly north of a comparable new Tokyo Marui Glock replica in cost. But starts to fifty-fifty out in one case you factor in overseas shipping. Keep in listen some of that actress padding is undoubtedly wrapped up in licensing. For anyone who actively buys officially licensed products (*cough* Lego Star Wars *cough*) you're already well familiar with the toll of doing business organization. C'est la vie.

I won this pistol through a raffle drawing at a local Pegasus Airsoft event; the pistol itself was generously donated by ThunderKissNW.

This volition non be so much a performance review as it is a detailing of the inner parts and workings of the gun. I was pretty dissatisfied with the lack of concrete details surrounding this pistol, so I decided to fully disassemble information technology to encounter for myself what's inside.

Exterior Features

This particular replica is reputedly a true i:1 of the real steel Gen. iii Glock 19 and information technology certainly feels that way. Different the TM G17 models, which are really modeled effectually the larger G21 in size, the EF G19 actually fits a G19 holster perfectly. The slide is nicely finished out in a smooth matte black finish, though the end doesn't quite match up to the real thing.

At that place are various trades constitute throughout, including series numbers, some of which are presumably unique to each replica. Of note, however, the serial number on the slide does non friction match that found on the lower.

The lower grip frame feels sturdy and does not flex when squeezed tightly in the hand. The light rail presents a very tight fit for real steel accessories, such equally the Surefire X300U, and y'all might struggle mightily to remove it after installing it. I did not feel any result with binding on the slide while running the gun with the Surefire installed.

The right side of the frame departs from the real steel with a few small differences, namely the "Officially Licensed Product of Glock" and a curious blank strip on the lower end of the grip which I believe is missing some text and is really borrowed from the Gen. four frame.

The underside of the trigger baby-sit is engraved with a alert label. For those who are curious, the engraving seems to be quite shallow, and I suspect it would be easily removed. It's not very noticeable in most lighting atmospheric condition for that affair. A serial number plate is found on the bottom of the rail segment and appears to accurately replicate the original.

The stippling is nicely washed – not besides rough, not too slippery. The magazine release is prissy and positive. Magazines drop free easily, and there is no binding or tight spots.

Coming from the HK45 / P30 / VP9 world, I admit that the Glock grip frame feels a bit like a ungainly brick and just points wrong for me. Similarly, I find myself struggling with the magazine release. With the HK serial I'thou used to just swiping my trigger finger straight down to release a magazine, no shifting of the grip required. Whereas with the Glock I have to shift my grip around to activate the magazine release. A training consequence, no doubt.

The magazines are nicely washed, featuring full Glock trades and even small details such as the round count indicators on the back. I find it a little inconvenient to accept to slide the magazine plate forward to fill the mag, so I may modern this by drilling a hole through the plate. Capacity is 19 rounds, which is iv more shots than you get with the real mag. We magazines are fully compatible with this gun.

The rear sight is a dovetail setup that is held in place via friction. To be honest, I find it very easy to press the sight off with just my fingers. I would propose for long term utilize to gum the rear into identify to continue it from coming off. The front end is retained via a pocket-sized spiral. I do not know now what compatibility this has with aftermarket sights or even existent steel sights.

Internal Features

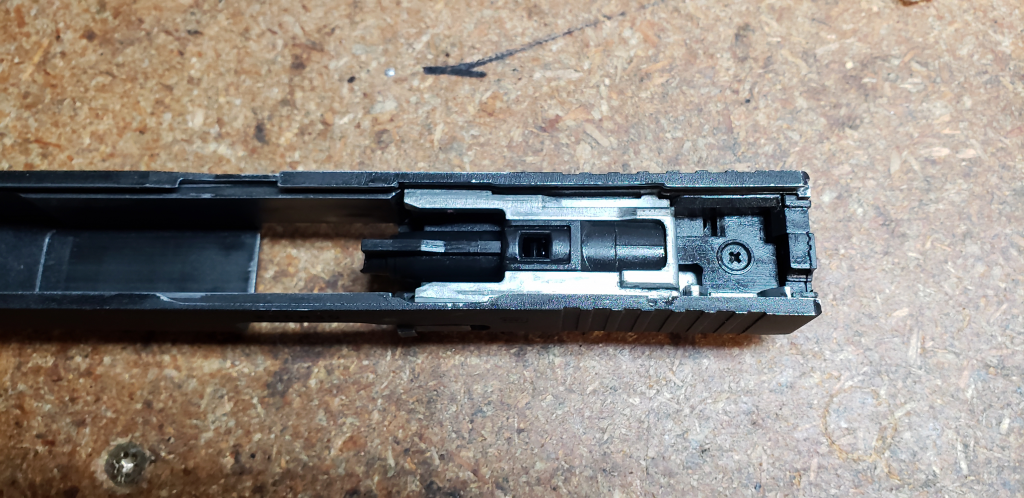

Basic field stripping of this pistol is quite like shooting fish in a barrel. Safe Queens will be happy to know that unlike the real Glock, you lot don't even have to pull the trigger to remove the slide. Merely pull down on both sides of the slide lock and pull the slide forward and off the the runway.

The barrel assembly is removed past first pulling gratis the recoil rod. This is closer in resemblance that found in the Gen. 4 Glock, and has a prepare of dual springs. The rod itself is plastic.

The outer barrel assembly is made from aluminum, and has the same matte finish as the slide. The correct side of the hood is engraved with Glock trades and a series number. In stock configuration, this comes with a threaded plastic orange tip that is also glued in place. This can be removed past boiling the butt for several minutes and then twisting the cap off with some pliers. I exercise non know what the internal thread pitch is of the barrel. If I had to guess, I'd say 11 or 12mm perhaps.

At present, Helix is currently the simply manufacturer making threaded outer barrels for these. I have read that TM outer barrels will fit with some minor modification, even so.

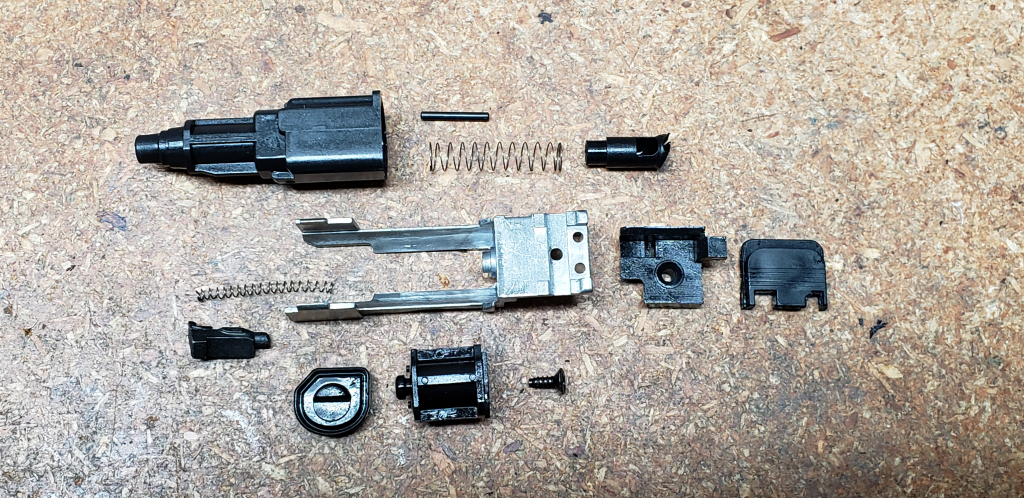

The inner butt and hop up chamber simply slide out the dorsum of the outer barrel. The barrel and bucking itself are TM uniform, as is the hop upwards wheel and diverse small hop upwardly components. The hop up sleeping accommodation torso itself is proprietary, but replacement parts are presently available.

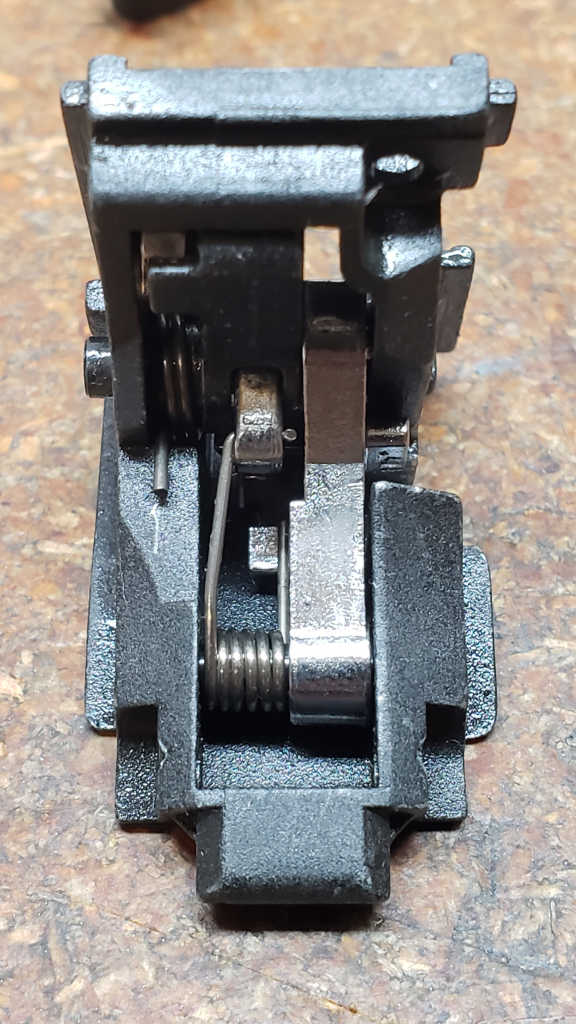

The air nozzle and housing is substantially a TM G18C setup. Unlike the TM version, however, this one is fabricated from metal. The nozzle return is assisted by a unmarried spring, which seems a bit on the weak side to me. I've noted that it seems a flake sticky when operated manually, which may be due to a weak spring and / or elevate from the metallic housing. I suspect a little polishing on the housing will smooth information technology upwardly some. Information technology does non present itself as an issue when firing the gun, though.

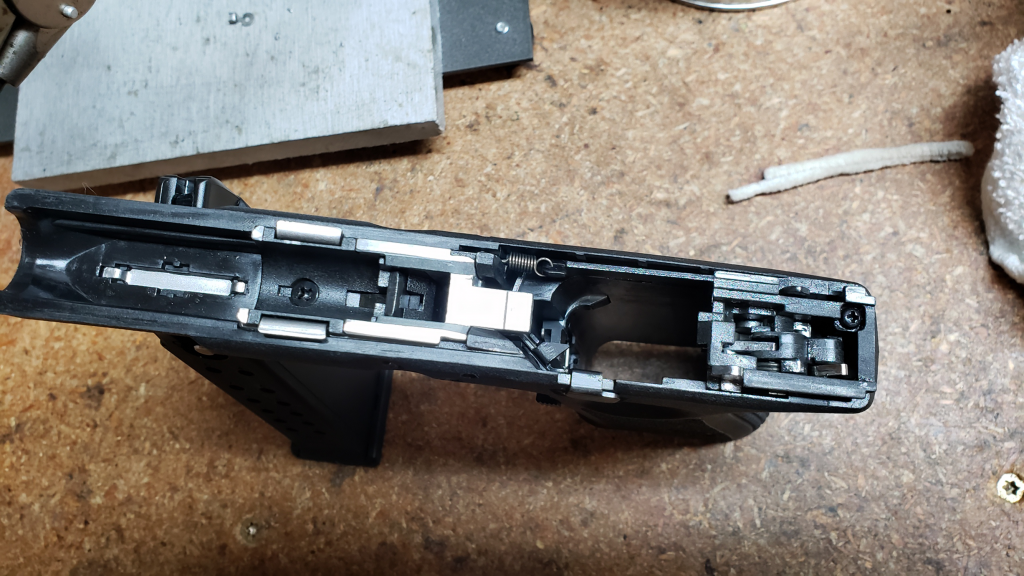

The frame is slightly more than complex, simply if you're at all versed with the real Glock teardown, some of the disassembly steps will be familiar.

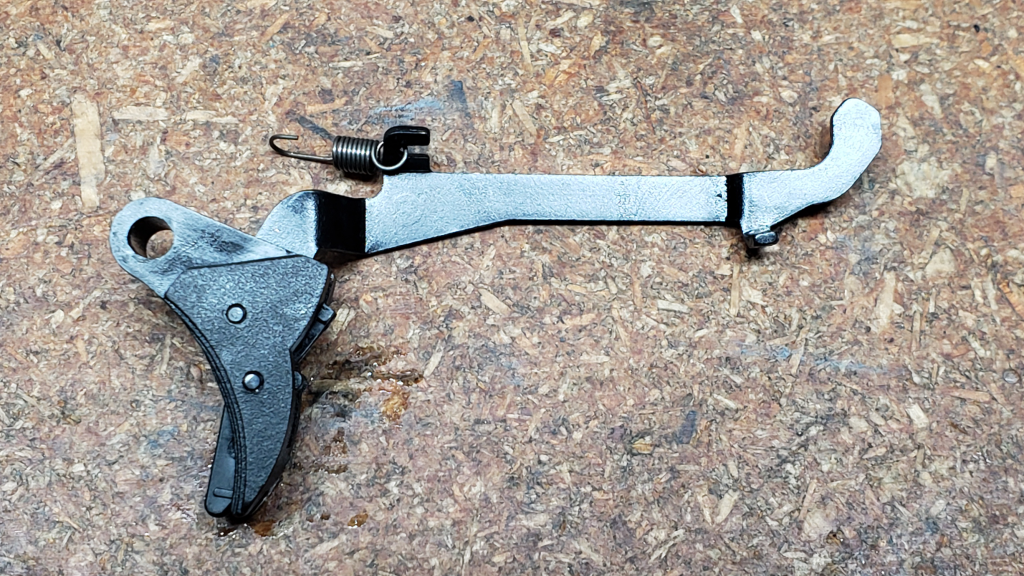

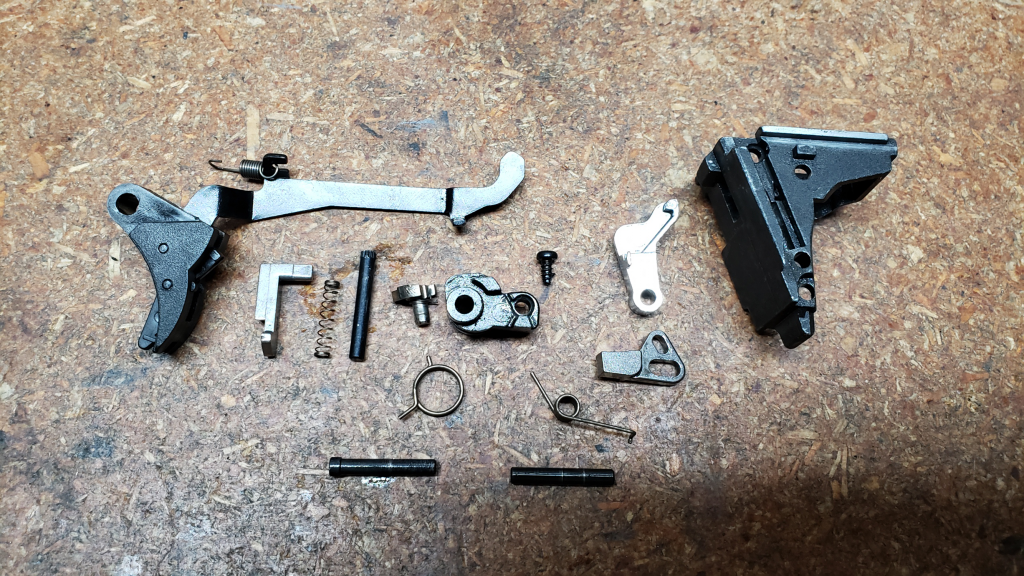

Starting with the locking block, press the 2 pins out from the right side of the frame. The slide release and jump will pop free, every bit volition the trigger bar render spring. The locking block tin so be pulled straight up and out.

I recommend leaving the lone spiral located in front of the locking block in identify in lodge to more hands remove the slide lock. This is accomplished by depressing the flat bound and sliding it out either the left or correct side. Later on this pace, you can remove the screw and the rest of the housing volition slide complimentary.

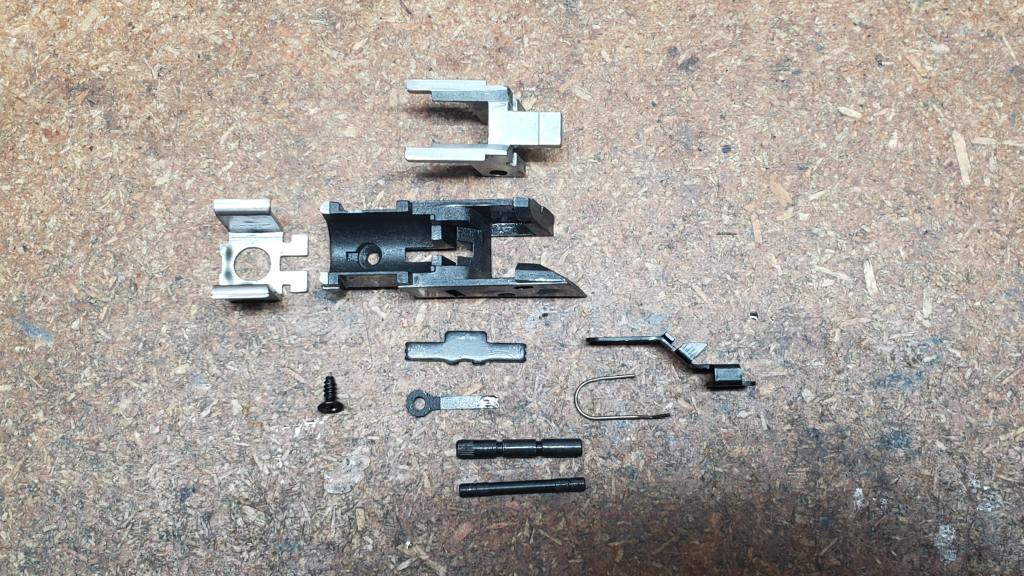

The slide release lever appears remarkably like the existent steel version, and I would virtually think this piece is compatible with real steel parts. Update 12/20/18: I have confirmed a existent steel Glock slide release fits perfectly. Unlike the real Glock, it's actually functionally usable in information technology's stock form likewise, and doesn't require a herculean effort to drib the slide.

On my instance, I discovered the locking cake surface was too high and was a meaning contributor to slide drag. it actually saturday higher than the slide rails themselves, and was bounden on the underside of the slide, causing the cylcling to exist sluggish and not at all smooth. A footling scrap of file piece of work fixed this easily enough.

At this betoken, the trigger is still essentially held captive by the fire command group chassis. This is removed by taking out the single screw and push pin located on the backstrap of the grip. Sliding this straight upwardly and out will free up the trigger and trigger bar. I do not know what kind of compatibility in that location is with aftermarket triggers or but the trigger shoe itself.

Some of these parts resemble TM parts, but without comparison them adjacent, I can't be 100% certain of their compatibility.

The final part to remove is the magazine release and bound. This is very uncomplicated, and by unhooking the spring from the magazine release you can slide it out the correct side of the frame. The magazine release has a metallic catch molded in, which is a nice touch as the magazines are also metal and should brand this office more durable than the full polymer mag release found in the real steel Glock. Granted, the real steel version uses polymer magazines.

Overall, disassembly of the frame was quite easy and did not present whatsoever unique challenges. The just tools really required are a modest punch and screwdriver. A dental pick can be helpful for reassembly of the valve striker bound. With a little familiarity nether your chugalug, you could easily do a full teardown in under ten minutes – though this is inappreciably necessary in the course of normal maintenance.

Last Notes

I was impressed with how piece of cake it is to fully detach this pistol. I am also pleasantly surprised with the the trigger pull too. It feels very much similar a existent Glock with a 3.5lbs Ghost Connector fitted… with an albeit very Glock-like "break", such as it is. It's quite unlike my KWA's which basically accept almost no takeup and but curl through the trigger pull. With the EF Glock, it's easy to stage the trigger.

Less impressive is the relatively poor stock accuracy, which I largely attribute to a below-average bucking. This is non an uncommon phenomena with stock guns though. With the exception of the TM, very few stock pistols have quality buckings installed from the manufacturing plant. I consider them "placeholders", essentially.

Installing a Maple Leaf 60* Autobot improved accuracy essentially, as did experimenting with a Maple Leaf Crazy Jet I stole from my VFC VP9 (despite it being a hair long). I take been told the Poseidon barrels are meliorate quality, then I figure now is as skillful a time as any to test information technology out, and have ordered up a Poseidon inner barrel and Maple Leaf bucking to supervene upon the stock components.

Perhaps my biggest complaint is the locking block consequence. Out of the box, this pistol had a very sluggish slide in addition to beingness heavily over-lubricated from the factory. It struggled to meander through a single magazine, and if you rode the slide manually you could cause it to stick partially open. The recoil was very weak. For most this would be a valid excuse to seek a warranty merits. As a tech, I would rather fix it myself than await on the often laborious and time consuming warranty claim process. I as well believe I can 'make it better' anyway, so to speak.

After filing down the height of the locking block and polishing the slide track both on the frame and slide, information technology operates a lot more smoothly now. I was able to achieve 4 full magazines on a single propane make full, with the slide fully locking back at the end of every empty mag. The felt recoil has greatly increased as well. It would be wrong of me to say that the locking block issue is representative of all Elite Force G-Series pistols, equally this is actually but a sample size of one – and thus far is the only one I've had exposure to.

In closing, I believe this pistol certainly has promise and I expect forward to running it difficult for the next year. The next review on this pistol will embrace some upgrades I volition be installing and additional compatibility findings.

Hk P30 Airsoft Spring Pistol Disassembly

Posted by: wilsonnohnerhed1967.blogspot.com

0 Response to "Hk P30 Airsoft Spring Pistol Disassembly"

Post a Comment